Comprehensive central facility monitoring system

2022-06-30

Intelligent system of clean rooms

2022-06-30

Previous

Next

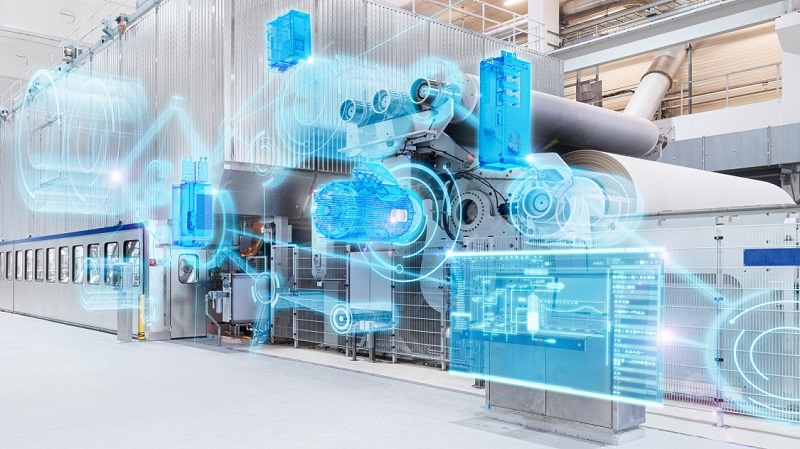

Intelligent maintenance system of facilities (TPM-RM01)

Annually, a lot of expenses are spent on the maintenance and repair of facilities and equipment of various industrial and commercial units. In most of these traditional units, the equipment is repaired or replaced in case of failure. With a proper planning in the matter of maintenance and repair of a center, in addition to reducing these exorbitant costs, it is possible to greatly reduce the time of suspension and shutdown of the equipment, which itself gives a big blow to the reduction of the productivity of this equipment.

- By identifying the equipment of different industries and the sensitivity of their performance, the Smart Construction Technologies Company has designed and implemented a smart maintenance system in two types of preventive maintenance and condition monitoring maintenance.

- In the type of preventive maintenance or PM (Preventive Maintenance), a certificate of the type, method and time of performing periodical repairs is defined for various equipment and stored in the system controller database.

- Using the existing database and the HMI screen, the relevant operator performs service and replacement of defective parts in the specified time periods.

- In this method, it is possible to report the history of repairs and the list of replaced parts, which helps to determine the performance status of the device and the financial estimation of costs.

- In order to reduce the costs of periodical repairs as well as the downtime of the overhaul of the devices, the manufacturing company suggests the use of Conditional Monitoring (CM).

- In this system, by continuously monitoring the operation of different equipment using special tools and sensors and observing and analyzing the behavior of each equipment in a central monitoring room, any deviation in the behavior of the vital parameters of the equipment will be detected by the system and the necessary warnings will be given to the relevant operator. Possible defects can be fixed as soon as possible. In this way, in addition to reducing the huge costs of periodical repairs or repairs resulting from the failure of parts, the downtime of the center’s critical facilities to perform basic repairs is also greatly reduced.

- It is highly recommended to use this system in centers with sensitive and expensive equipment such as hospitals (which include vital devices such as oxygen generators and sterile steam supply boilers) as well as refineries, petrochemicals, power plants, pharmaceutical factories, etc. , because repair costs and non-stopping of equipment in these centers are very important.